What Is Supply Chain Management, and Why Is It Important?

Most of us hardly think about what it takes for a product to reach us. We make a payment, and we enjoy it. What supply chain management (SCM) means is not important to the person on the street. And that is how it should be.

But not for a person who delivers products to customers. You can only do an excellent job if you understand how the system in which you operate works. The majority of people would be surprised to know what it takes for a product to reach them. Even a seemingly simple product like biscuits. It could also shock them to find out how many people take part in the process.

The Supply Chain of a Packet of Biscuits

The process of preparing a packet of biscuits starts at multiple locations. It also involves the efforts of various actors. There is a farmer who grows wheat, the primary ingredient. Then there is a sugarcane farmer, the source of sugar. And there is a dairy farmer who produces the milk.

Others in the list of raw material sources include food colouring, salt, baking powder, eggs, yeast and cooking oil producers. You could also add cooking equipment manufacturers to this category. This list is far from conclusive. It can be really long if we add each item that is critical to the delivery of a packet of biscuits.

You’ve probably also noted that we can go even further back with the source of raw materials. For example, the wheat farmer has to source seeds, fertiliser, herbicides, farm equipment, and other items. And all these cost money to bring to the farm. Indeed, it is hard to find the actual beginning or starting point of the process to get you a biscuit packet. It costs money to transport the raw materials to the biscuiteer’s premises.

It also takes some loading and unloading costs as well as insurance cover. The company that produces biscuits has to engage the services of machine operators, bakers and cleaners. The plant also requires electricity, water supply, insurance cover, and other things. When the biscuits are out of the oven, they need packaging. Someone has to deliver the packaging materials.

Manage the Flow of Goods, Information and Money

But before that, someone else has to do the necessary graphics work on the packaging material. They have to print the biscuit company’s brand name, colours and marketing content. They also have to print essential consumer information.

Once they package the biscuits, someone else has to transport them to the distributors. The distributors, in turn, have to bring them to the local store. The transportation costs fuel, driver’s salary, loading and unloading wages and insurance cover. Not to forget the warehouses where the biscuits have to stay while in transit. Finally, the customer can buy biscuits at the retail store. They are oblivious of the numerous activities and people involved. It is important to emphasise that a lot more is involved than what we’ve described above.

We didn’t mention every person, activity, and cost item that goes into making the packet of biscuits arrive at the local store. Nevertheless, the complex system we attempted to describe above is what supply chain management is all about. Supply management is everything that goes into putting a product at the hands of a consumer. In particular, what SCM does is to oversee the chain of suppliers, manufacturers, distributors, and retailers.

It makes sure they use sustainable material, energy, labour and production methods. This is to produce a quality product that comes at the least cost possible. Supply change management also involves making the flow of the product, related information and money from one end to the other smooth. The process is also known as purchasing and supply chain management.

What’s Supply Chain Management System

Supply chain management system is a computer application. It makes SCM easier. The system receives data and processes it into information. This leads to appropriate business decisions. It has a user interface on a computer where the data goes in. It is also where users can access information. The application is connected to a server that executes and stores data. SCM systems have changed considerably over the years.

Before computers and the internet, businesses handled supply chains and logistics through physical paperwork. This was slow and cumbersome. It took a lot of effort to meet existing needs. Computers made things easier. Businesses can effortlessly process huge amounts of data. They can also access information faster. We’ve witnessed supply chain management systems transform from on-site hosting to cloud-based services. Businesses don’t have to worry about the technical workings of the systems they use. All they do is create an account on a cloud solution.

They can choose one of the several supply chain companies have set up. And they can do this through a browser, and start running a system. In recent years we’ve also seen the addition of artificial intelligence (AI) and the internet of things (IoT) into the supply chain management systems. Now, for example, it is possible for a retail store to know the exact temperature in a container that is delivering perishable goods. That is because censors inside the container can send that data in real-time. The new addition to SCM systems is blockchain. This is a technology that could secure the integrity and validity of data that comes from multiple points on the supply chain.

Sticky Learning ® is 7 times more effective than 1-day training courses. Plus, you will get a Chain of Evidence proving your Return on Investment. Discover soft skills training that changes behaviours long term.

How SCM Works in Retail

It is hard to separate supply chain management in the retail or grocery industry from what happens elsewhere. That is because all supply chains end with a consumer. When people mention supply chain in retail, often what they are referring to is the supply chain that ends at a retail store, supermarket, or a mini shop. How supply chain management works in retail is mostly similar to what we described in the introduction of this post. But a few unique features exist.

We can handle these in two broad categories — Supply chain management in physical retail shops and supply and management in online stores. Most physical retail stores are sole proprietorships and companies. These entities buy goods either from the primary sources such as farmers and manufacturers or from distributors. Most retail stores accept delivery of goods along with the responsibility and risks involved.

If the goods are never bought or they perish, then the loss is for the retail store. A few others accept delivery with an understanding that the goods still belong to the supplier. Sometimes they do not sell or the products outlive their usefulness. When that is the case, the retail store doesn’t pay for them. The supplier counts it as its own loss.

How Supply Chain Management Is Used with E-Commerce

Similar to category management e-commerce, supply chain and logistics management in e-commerce are a little more complicated than what happens in physical stores. In some cases, the manufacturer owns the e-commerce site. This results in direct sales from the manufacturer to the consumer. Other e-commerce sites are by retailers who buy from manufacturers and suppliers.

But online supply chains use a few other arrangements. One of those is where the e-commerce site is simply a third-party marketplace that matches buyers and sellers. A good example of that is Aliexpress.com. Manufacturers and distributors post their products. Shoppers make purchases. The site owners get a fee from the transaction. The manufacturer or distributor ships the product. Another unique online supply chain is what is known as dropshipping.

This is where someone creates an online store that links to an e-commerce site by a manufacturer or distributor. When a buyer makes a purchase, the store automatically sends the order to the manufacturer who then ships the product directly to the consumer. Meanwhile, the owner of the store receives payment from the shopper and settles the manufacturer.

How Supply Chain Management Works in Amazon

Amazon is the largest online store in the world. It is also among the very first to come online. Close to 50% of all products people buy online go through Amazon. Two primary types of supply chains exist on Amazon. The first is known as Amazon Vendor Central. This is where suppliers and distributors sell in bulk to Amazon. In turn, Amazon sells and ships to customers around the world.

The second model is known as the Amazon Seller Central. This is where Amazon lets independent businesses and individuals list their products on the site. These individuals and companies then have to deliver the product to Amazon fulfilment centres. In these centres, the products are packed and shipped through what is known as fulfilment by Amazon (FBA).

In both models, Amazon handles customer service.

How Supply Chain Management Is Different from Logistic Management

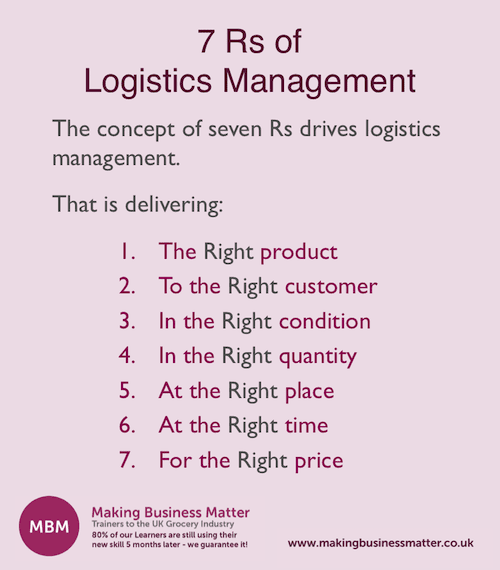

Frequently people use logistic management and supply chain management interchangeably. They also sometimes use them together—as logistics and SCM. But are they the same thing? Not really. However, in most organisations, the person in charge of supply chain management is also the one who takes care of logistics management. Logistics management is part of SCM.

Logistics management is everything in the supply chain that is related to transportation and in-transit storage of raw materials and products. The entire process of collecting raw materials, processing or transforming them to a product a customer desires and getting it to them is supply chain management. But the movement of raw materials and products, as well as their warehousing is logistics management. Supply management and logistics management have the same goals though. And these are to improve efficiency, deliver quality and minimise costs.

How Supply Chain Management Helps in Business

Price, quality and customer experience are the three critical factors that determine a business’ competitiveness at the marketplace.

If a business wants to deliver the best deals on price, quality and customer experience, it has to control the inputs. That is the raw materials, services as well as cost.

How Supply Chain Management Reduces Inventory Cost

What a supply management system does is to help the business to keep track of inputs and costs. If the end product is more expensive than its competitors, the business can check its supply chain system.

That can help it identify possible links it can replace with less costly ones. And this is in a way that doesn’t compromise quality.

It also helps keep costs down by making it easier to identify middle persons that add no real value to the supply chain. The business can eliminate them and recoup their cost.

How SCM Can Increase Profits

It helps a business to know where everything comes from and to maintain quality. The company can monitor the entire process of making the product available to the end customer. Supply chain management determines whether a business remains competitive in the marketplace.

If the supply chain is not monitored, it could easily lead to one of the following:

- The cost could skyrocket and make it hard for the business to compete with others.

- Inferior materials could get into the process and lead to bad customer experience. This, in the long term, also leads to the business losing a market.

Are Supply Chain Management Jobs in Demand?

Every major business has a person in charge of supply and chain management. This person is generally known as the Supply Chain Manager. The job title in some organisation is the Logistics and Supply Chain Manager. There are other variations as well. The globe is becoming competitive for business as countries open up their borders for goods and services.

A company that can produce quality products at the cheapest cost possible through an efficient global supply chain wins. Companies and businesses are hunting for people who will help them achieve efficiency in their supply chains.

A report by the global supply chain logistics company DHL has provided estimates from the U.S. Bureau of Labor Statistics that forecast a growth of 26% of jobs in logistics between 2010 and 2020. According to the same report, global supply chain management talent exceeds supply by a six to one ratio. So yes, jobs in SCM skills are in high demand. But is supply chain management a good career?

Yes, it is especially if you have the patience to learn the necessary skills. According to Totaljobs, the average salary supply chain professionals in the UK is £42,500.

Where to Study SCM

Supply chain management is a subject of study in many business schools in the UK and around the world.

You can study to acquire a supply chain management degree, diploma, or certificate from one of the many UK colleges. There is also a variety of choices if you choose to do masters (MSC) in SCM.

Another option you have is to enrol in online courses. This gives you the flexibility to study according to your own circumstances.

You can also get into an organisation as a junior staff and get to learn on the job. Many companies do engage external trainers to help their team acquire supply chain management skills.

The training can be followed up by certification on logistics & supply chain management by bodies like The Chartered Institute of Logistics and Transport (CSCP) and Chartered Institute of Procurement and Supply (CIPS).