Get Your Suppliers ‘Sorted’: Start Here

The Kraljic Model helps businesses manage their supply chains by segmenting suppliers into classes and using that knowledge proactively. The perfect story is working with local suppliers you know and trust. But buyers across the sectors increasingly have to deal with distant suppliers and complex supply chains. This can lead to a sense of “us and them,” and all that brings. The Kraljic Model helps you analyse your supplier relationships and work towards the ideal of ‘win-win’ negotiations and co-creation.

This article explores how the Kraljic Model, AKA Kraljic Matrix, helps you develop effective strategies for different suppliers. Also, we look at how a global soft drinks manufacturer uses it to manage its raw materials vendors. From there we see how the Matrix fits into the “next normal” goal of digital transformation. And inspired by the 1999 sci-fi movie, we end on how to escape ‘The Matrix’ by achieving transparent supplier partnerships.

What is Kraljic’s Procurement Model, and Why Do People Use it?

In 1983 Peter Kraljic, a director of McKinsey Germany, wrote about his ‘Kraljic Model’ in Harvard Business Review. Companies worldwide have found it a useful tool since then, and continue to, despite the time that’s passed.

Kraljic’s Model helps purchasers maximise their supply security and minimise possible disruption, by analysing individual suppliers. It enables them to manage their purchasing portfolios, develop procurement strategies and optimise their buying power.

This approach transforms procurement from a simple, transactional activity to a strategic process at the heart of the business. Ideally, leadership needs to have oversight, building relationships with suppliers at the senior level. But you can work towards that over time.

Meanwhile Back in The Real World

It’s not that easy. Unforeseen events can and do happen and, as recent events show, you can become seriously exposed. For example, energy companies rely on gas supplies. In food and drink, baking our daily bread needs key ingredients like wheat. For years, Britain’s dependency on the trading relationships around these commodities seemed perfectly acceptable. And then Russia invaded Ukraine, and the price of those commodities rocketed upwards. You can’t rewrite history. But Kraljic’s model can help you react better to the situation now.

A First ‘Class’ System For Managing Your Procurement

Kraljic’s model segments businesses’ purchases into four classes,’ or quadrants. These have two dimensions:

- The complexity, or risk, of the supply market: this includes factors like distance, monopoly or near-monopoly situations and technological innovation. Suppliers’ sustainability credentials, and their countries’ political situations and human rights records, increasingly affect consumers’ choices. So you need to consider how your customers will react, whether they’re businesses or consumers when selecting possible suppliers.

We‘ve mentioned Russia and Ukraine but, another high-risk supply market at the moment is China. For many years Western companies were more than happy to do business with them. But that was before COVID. The UK doesn’t rely completely on Chinese-produced goods, but we’re a pretty big trading partner. COVID in China has caused and is causing, supply chain bottlenecks. We’ll look at those in a moment.

- The suppliers’ importance: this is based on your assessment of their impact on the profitability of your business. As we said, if you see procurement as strategic and central to your business, leadership should have oversight. And ideally, they should be involved in your relationships with key suppliers.

Sticky Learning ® is 7 times more effective than 1-day training courses. Plus, you will get a Chain of Evidence proving your Return on Investment. Discover soft skills training that changes behaviours long term.

The Kraljic Matrix Helps You Get The Picture

It can speed your decision-making if you express things visually. You can do this with the Kraljic Matrix.

The Kraljic Matrix maps a product’s profit impact on one axis, and the supply risk on the other. It provides a portfolio management approach to managing your suppliers. You can select, prioritise and control your purchasing, in line with your other objectives. The Kraljic Matrix lets you see which supplier relationships are particularly important, so you can handle them strategically. You can also identify which items you buy are less important and decide how best to manage sourcing them.

Take a Four Square View of Your Suppliers

The Kraljic Matrix puts suppliers and products into four quadrants:

Analysing your purchases like this enables you to define the best purchasing strategies for each one. But ideally you should inform your analysis with knowledge and trust, rather than assumption. As we said, get to know your suppliers personally. Let’s look at the quadrants:

Leverage Items

These have a high financial impact on your business, and you spend a lot on them. But the good thing is, they’re in abundant supply. These items are usually highly standardised, and easily available. This quadrant is a buyer’s market. You, the customer, hold the balance of power and can leverage your strength to obtain greater returns. And that usually means, you force the price down.

Best Purchasing Strategy

Typically, the strategies people use for these types of items include tendering and competitive bidding. The difficulty is this doesn’t help build positive supplier relationships. And if the suppliers get resentful about this treatment and group together, the situation changes completely. Then they turn into strategic items, or worse, bottleneck items.

Strategic Items

These have a high supply risk and a high-profit impact and are brought mainly from strategic suppliers. These items are often mission-critical to the buyer’s business. The goal is to ensure long-term availability, recognising the balance of power between the supplier and the buyer.

Best Purchasing Strategy

Look for a “win-win” solution that benefits both parties. If you don’t, the purchaser will run out, causing a bottleneck or worse.

Bottleneck Items

These are products with a limited source of supply, causing bottlenecks if they’re unavailable. They often have a relatively limited monetary value, but often can only be obtained from one supplier, or very few. Bottleneck items can include CPUs and power packs for laptops and microchips for cars. The supply risk is high – you might run out – but these items don’t usually have a major profit impact. So, this quadrant is a supplier’s market. However, unlike leverage items, power is in the suppliers’ hands. They can behave freely and force prices upwards if they so choose.

Best Purchasing Strategy

First, ensure the continuity of your supply. Second, develop plans to reduce dependence on this supplier. That means thinking about adapting your products and investigating other products and suppliers. Meantime it’s advisable to make your negotiations with the current supplier a win-win.

WARNING: It’s Not Just Items You’re Buying That Cause Bottlenecks! It Could Be Your Processes.

Procurement departments can make their challenges worse by internal bottlenecks slowing things up. This can happen in these areas:

- Approval processes and workflows.

- Supplier relationships and supply chain management.

- Spend analysis.

- Lead time management.

Are you using out-of-date software? Or paper-based systems to confirm orders, rather than email? You may have great eProcurement tools and supply chain EDI systems. But are you getting the most out of your sales data, and sharing it with your suppliers in joint business plans? It takes effort to get to this stage, but it’ll be worth it.

Here are some other things that contribute to bottlenecks:

- Disruptions to production and staff sickness.

- Suppliers’ production processes and capacity issues cause queues and waiting times.

- Supply chain delays, with goods coming on container ships or lorries stuck in ports.

And of course, everyone in the chain is probably facing bottlenecks of their own.

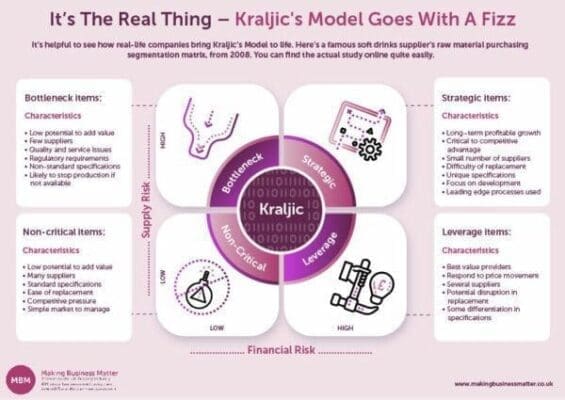

It’s the Real Thing – Kraljic’s Model Goes With a Fizz

It’s helpful to see how real-life companies bring Kraljic’s Model to life. Here’s a famous soft drinks supplier’s raw material purchasing segmentation matrix, from 2008. You can find the actual study online quite easily.

Bottleneck Items:

Characteristics

- Low potential to add value.

- Few suppliers.

- Quality and service issues.

- Regulatory requirements.

- Non-standard specifications.

- Likely to stop production if not available.

Strategic Items:

Characteristics

- Long–term profitable growth.

- Critical to competitive advantage.

- Small number of suppliers.

- Difficulty of replacement.

- Unique specifications.

- Focus on development.

- Leading edge processes used.

Non-Critical Items:

Characteristics

- Low potential to add value.

- Many suppliers.

- Standard specifications.

- Ease of replacement.

- Competitive pressure.

- Simple market to manage.

Leverage Items:

Characteristics:

- Best value providers.

- Respond to price movement.

- Several suppliers.

- Potential disruption in replacement.

- Some differentiation in specifications.

Looking Beyond The Matrix

Kraljic’s Matrix covers the four quadrants, bottleneck items, strategic items, non-critical items and leverage Items. The soft drinks company’s report also highlighted these additional factors to consider in analysing suppliers:

- Product, service, quality.

- Continuity, capacity, the complexity of specifications, social responsibility.

- Supplier’s relationship with competitors.

- Financial stability, industry dynamics, environmental issues.

- Availability of suitable suppliers, supplier also a customer.

Other factors the company also considered in evaluating suppliers were:

- Innovation and technology: intellectual property: supply chain process integration: minority/women owned businesses.

- Global presence: competitive pricing: cost management: volume/spend.

- Compatibility/strategic alignment: access to assets and capabilities: impact to cost, quality, delivery, profitability.

- The company’s attractiveness as a customer: not every supplier might want to do business with you, for whatever reason. What might put people off trading with you?

Are You Using Kraljic’s Model Effectively ? Check These Procurement KPIs.

You Pay Less (Reduced Cost):

- Procuring supplies, services and contracts at the best price.

- Better visibility into your budget and how funds are being spent.

- Ability to leverage cash flow by extending payment terms and forecasting for the future.

Things Work Better (Greater Efficiency):

- Goods and services are delivered on time.

- Finding solutions to unforeseen circumstances like labour shortages, natural disasters and economic and political instability.

- Ability to distinguish between effective and underperforming suppliers.

- Improved supply chain and possible compensation from underachieving suppliers.

You Stay Ahead of the Rest (More Innovation):

- Effective procurement helps you find innovative products or services to offer your customers

- You may also be able to secure exclusive deals with the consumers

Carry on Up the Amazon – It’s a Digital Future, Now

Now let’s see how Kraljic’s Matrix fits into the “next normal” goal of digital transformation. If you want to be ahead of the competition, or at least keep pace, you need to go digital.

If you want to know more about current procurement best practice, Amazon Business offers a simplified online guide. They also offer something called The Enterprise Procurement Playbook.

Why Digital Transformation is Important

A 2021 survey by Deloitte concluded the pandemic has brought a new focus on supply chains and robust, resilient and agile procurement. And Brexit’s after-effects, the Ukraine war and rising energy costs have made things worse. Whoever you choose as your digital transformation mentors, digitising your procurement will make it easier to meet sourcing demand, boost productivity and maximise costs.

Kraljic’s Model – It Works Like Therapy

Kraljic’s Model helps you manage your anxieties about your suppliers. By dividing them into quadrants, you identify what could cause problems in the future. Then, from there you can decide how you choose to respond, based on assessing what your suppliers are like. Furthermore, you can take this assessment to high levels of sophistication, like the soft drink company in our example.

Being proactive like this will help you predict situations and manage how you react. Yes, unexpected stuff happens and it’s not going to be smooth going. But Kraljic will make you better able to be proactive and anticipate problems.

Being proactive is habit number #1 in Stephen R. Covey’s international bestseller, the 7 Habits of Highly Effective People. Proactivity means not letting adversity defeat us. We can’t choose what happens, as Covey points out. But we can choose how we react and get closer to the goal of co-creation.

We’re Trapped in the Matrix

Kraljic’s Matrix provides a method for supplier segmentation. Putting suppliers into sections gives a clearer idea of the resources, priorities and objectives you need. But there are downsides:

- It’s time-consuming and challenging. You may uncover issues that make you question your choice of suppliers. But real-world pressures may mean you have no time to change.

- Supply bases can change rapidly, based on real-world events: disruptions to supply chains, political changes in country markets, shortages of container ships, wars, terrorism, natural disasters.

- Your suppliers can make a segmentation analyses on their customers and decide not to trade with YOU. If this happens, they’re also making theories based on the available information. So, there’s uncertainty and incomplete information on both sides, no trust and no relationship. Like in the sci-fi movie, you and your supplier are trapped in The Matrix!

You Can Escape the Matrix – But Until You’re Ready to, it’s Pretty Useful

In business, everyone has the individual responsibility to make a choice about how they work with their suppliers. There’s the “artificial world,” where you don’t really know your supplier, only the knowledge you’ve gathered about the outcomes they can deliver. That won’t help you know and trust them, and it affects your expectancy of what each other can deliver. Then, there’s the “real world,” where you know each other very well and achieve great things together.

What you really want is total openness, honesty and communication between buyer and supplier. You need to build relationships. Visit them, get to know them. If your potential suppliers are overseas, go on buying trips. Visit trade shows. Talk to their agents here. Visit their country offices, talk at the highest possible level, and let them see you value the relationship. And while you’re working on that, Kraljic is a pretty good Model to work on.